Optimisation is about selecting the most efficient actuator that will consume the least power to provide the best operating performance of the actuated valve. In order to achieve this, one must be competent in both valve and actuator knowledge.

OVS engineering team has a combined experience of more than 50 years serving the valve industry and utilise this experience to develop our own unique programs and software to optimise our flow control solutions for you.

Our sizing programs cover the three most common actuation needs that is demanded in the valve industry - motorised gate valves, motorised quarter turn valves and actuated shutdown valves.

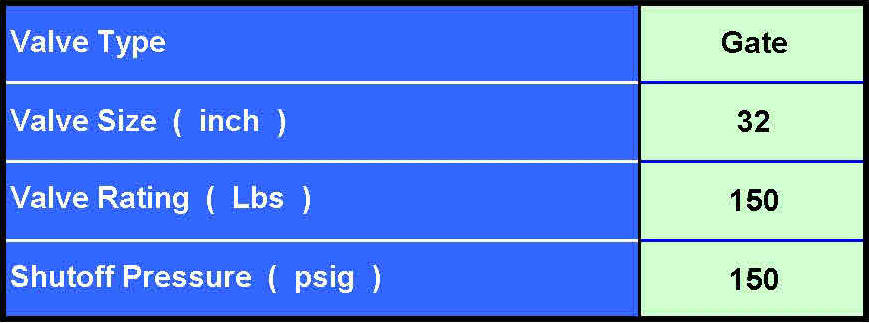

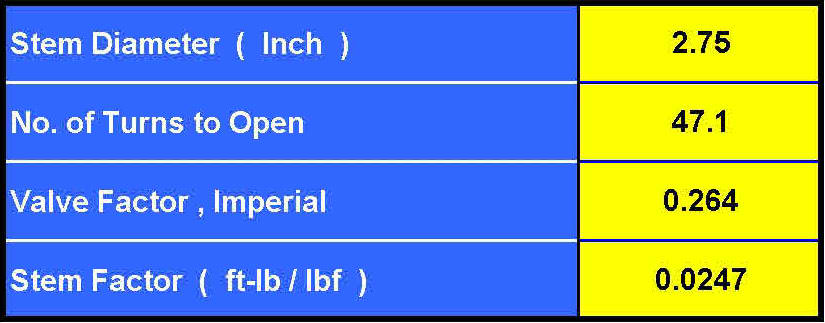

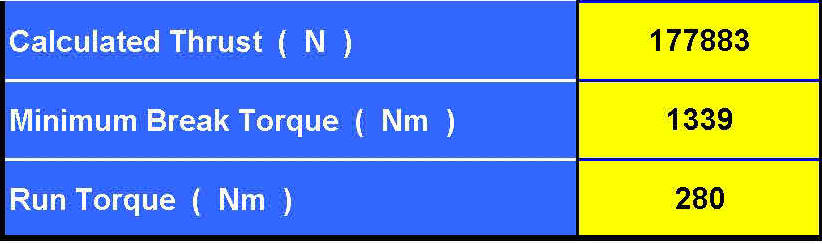

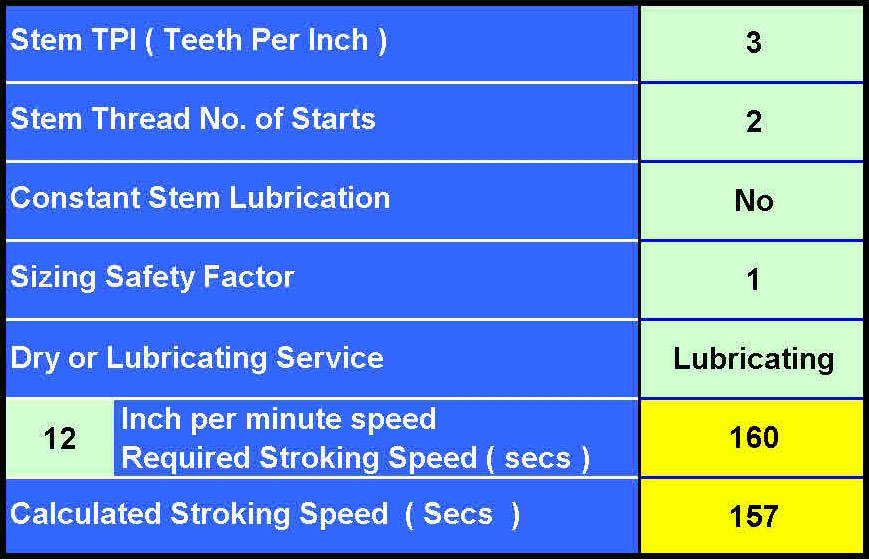

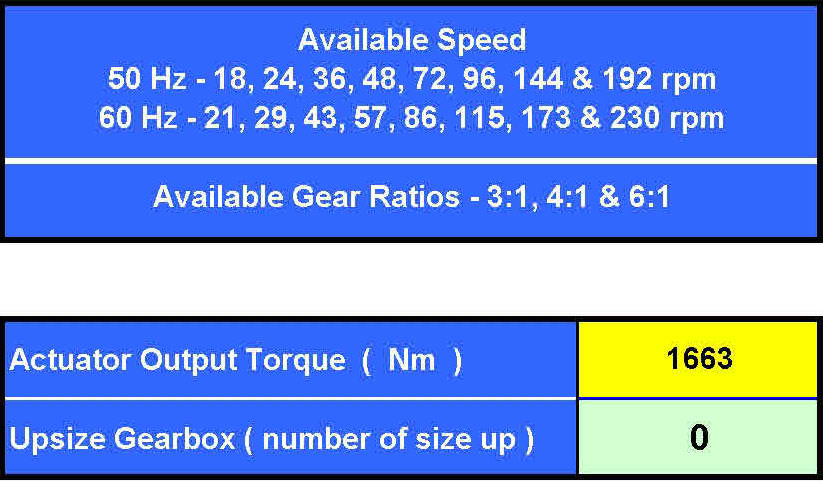

OVS MOV gate and globe valve sizing program combined the engineering features of the API gate/globe valve with many of the world’s leading actuator vendors and selects an optimized actuator to match the valve.

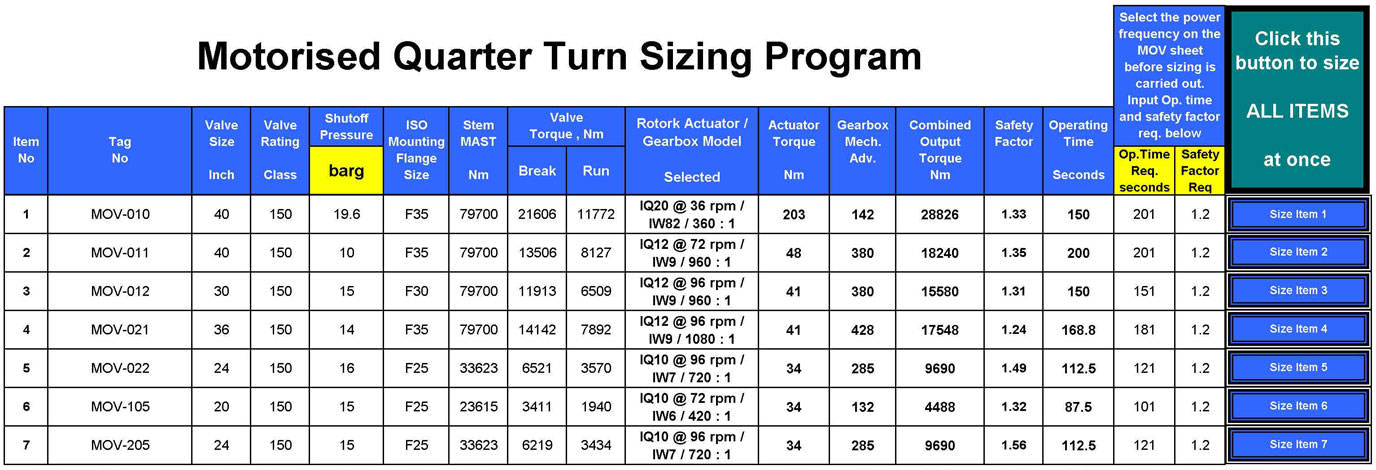

Our quarter turn sizing program takes into consideration many factors that are critical yet often neglected. Other factors and properties such as high temperature, abrasive services and differential pressure drop are all situations that are considered on the valves and factored into our sizing program. This allows OVS to select optimized actuators to meet the demands of the service.

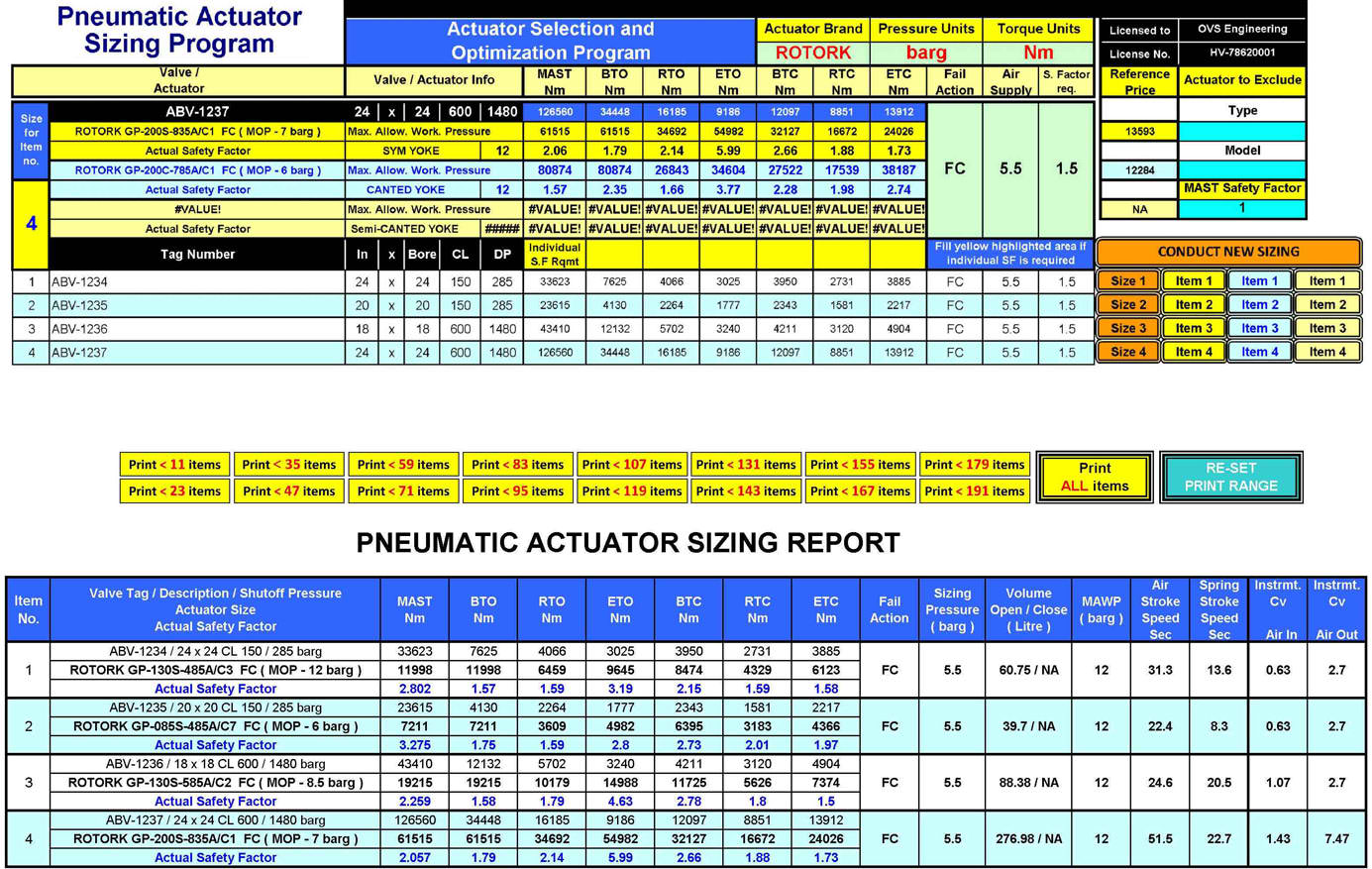

We understand control logics of shutdown valves and use our sophisticated sizing program to best match the valve with its actuator. Our sizing program takes into account the least air pressure required to achieve maximum safety margins with minimal air consumption. Additionally, the program is able to accurately size the proper instruments to achieve desired stroking speeds instead of oversizing them. Our cooperation with many established actuator vendors allow various actuator options to be selected.

Many in the valve industry believe that selling valves is just about matching the specifications provided by the client and their product. At OVS, we believe differently and offer our clients the following four stages of service.

During the FEED stage, our engineers work hand in hand with end users and EPCs to discuss technical and engineering aspects with regard to valve and actuator applications and other flow control equipment that we are supplying.

OVS actively source for the best valves and actuators that can meet the client needs. Best does not mean the most expensive but products that give the client the most value for their money. Quality valves that are proposed are stringently tested at the factories and also checked at our workshop before they are shipped to the client.

Understanding the importance of a strict project timeline, OVS consistently checks with the valve/ actuator factory and provide regular production updates to the client ensuring that we deliver the valves on time as promised.

A team of engineers are also trained to assist our clients during their installation and commisioning stage of their projects should they require our assistance.

Buying a valve is no different from buying a car. Valves require the proper installation and maintenance to guarantee a long service life in your plant. OVS provides onsite service contracts to clients who require them and also offer to conduct valve maintenance classes for your plant engineers to understand and maintain the valve more efficiently.

LOCATE US

OVS Engineering Pte Ltd

39 Woodlands Close, #02-60

MEGA@Woodlands

Singapore 737856

CONNECT WITH US

T: +65 6810 4170

F: +65 6810 4174

EMAIL US

sales@ovseng.com